MULTISPAN UTC -1202G-RG-A2-X0

Price 1210 INR/ Piece

MULTISPAN UTC -1202G-RG-A2-X0 Specification

- Screen Size

- 0.56 Inch

- Features

- Dual display, High/Low alarm, Universal input, User programmable

- Weight

- Approx. 170g

- IP Rating

- IP20

- Phase

- Single Phase

- Remote Control

- Yes

- Load Capacity

- 5A @ 230V AC Resistive

- Control Type

- Digital

- Frequency

- 50/60 Hz

- Connectivity Type

- Relay Output

- Processor Type

- Microcontroller Based

- Sensor Type

- RTD / Thermocouple

- Mounting Type

- Panel Mount

- Automation Grade

- Automatic

- Application

- Process Control & Automation

- Material

- ABS Plastic

- Power

- 100-250 V AC/DC

- Temperature

- 0 to 60C

- Voltage

- 100-250 V AC/DC

- Number of Output Relays

- 2

- Size (mm)

- 96 x 96 x 52 mm (WxHxD)

- Cutout Size

- 92 x 92 mm

- Output Type

- Relay (SPDT), SSR, or Analog out

- Input Type

- Universal (RTD, Thermocouple, mA, mV, V)

- Sampling Time

- 250 ms

- Display Type

- 7 Segment LED, Dual Display

About MULTISPAN UTC -1202G-RG-A2-X0

MULTISPAN UTC -1202G-RG-A2-X0

AUX VOLTAGE :- 100-270V AC (SMPS)

OUTPUT :- 1R1C /O/ 1SSR+1R1C/O

ACTION :- PID/ TP / ON-OFF SELECTABLE

SENSOR :- UNI, I/P (J , K , PT-100)

| J/K/Pt-100 (Selectable) 100-270V AC |

Universal Compatibility for Process Control

The UTC -1202G-RG-A2-X0 accepts a broad range of input types, including RTD, thermocouple, mA, mV, and voltage signals, making it ideal for diverse automation setups. This flexibility lets users integrate the controller into various automation workflows, simplifying inventory for manufacturers and system integrators.

Efficient Dual-Display Readability

With a dual 7-segment LED configuration and 0.56-inch screen size, users can view two process parameters simultaneously. Clear, efficient visuals help operators monitor and react to changes quickly, improving safety and reducing manual errors.

User Programmable Alarms and Outputs

Equipped with high/low alarm functionality and two output relays-selectable as SPDT relay, SSR, or analog out-this controller offers customizable control for a variety of process applications. The simple programming interface saves setup time for technicians.

FAQ's of MULTISPAN UTC -1202G-RG-A2-X0:

Q: How can I connect different sensors to the UTC -1202G-RG-A2-X0 controller?

A: The controller supports universal inputs, including RTD, thermocouple, mA, mV, and voltage signals. Simply match your sensor's output to the appropriate terminals, and use the programmable interface to specify the input type for accurate process measurements.Q: What benefits does the dual display offer in industrial applications?

A: The dual 7-segment LED display allows operators to monitor two parameters at once, such as process value and set point. This improves real-time awareness, enabling faster response to process changes and reducing the risk of error.Q: When is it suitable to use the UTC -1202G-RG-A2-X0 in automation processes?

A: This controller is ideal for process control and automation where accurate, reliable monitoring and control are required-such as manufacturing lines, HVAC systems, or laboratories. Its universal input compatibility and alarm outputs make it versatile for many tasks.Q: Where should the controller be mounted for best results?

A: The controller is designed for panel mounting and requires a 92 x 92 mm cutout. Install it in control panels within the specified ambient temperature range (0 to 60C) and away from excessive moisture or dust, as it carries an IP20 protection rating.Q: What is the process for setting up high/low alarms on this device?

A: Use the front panel controls to access the programming menu. You can set the desired alarm thresholds for high and low values. Once configured, the output relays or SSR/analog outputs will trigger based on your programmed criteria.Q: How does using this controller benefit process automation?

A: This model delivers precise, programmable control, rapid 250 ms sampling, and robust alarm options. It enhances reliability, reduces manual intervention, and adapts easily to a variety of process automation demands, ultimately improving operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Automation Systems Category

C&S MCB CSMBS1C6NR12 SP 6A

Price 107.3 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 240V AC

Frequency : 50 Hz

Application : Low Voltage Circuit Breaker for Residential/Commercial

C&S MCB CSMBS4ISO40NR03 ISO 40A

Price 1610 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 240/415V AC

Frequency : 50/60 Hz

Application : Suitable for Residential, Commercial, and Industrial Electrical Circuits

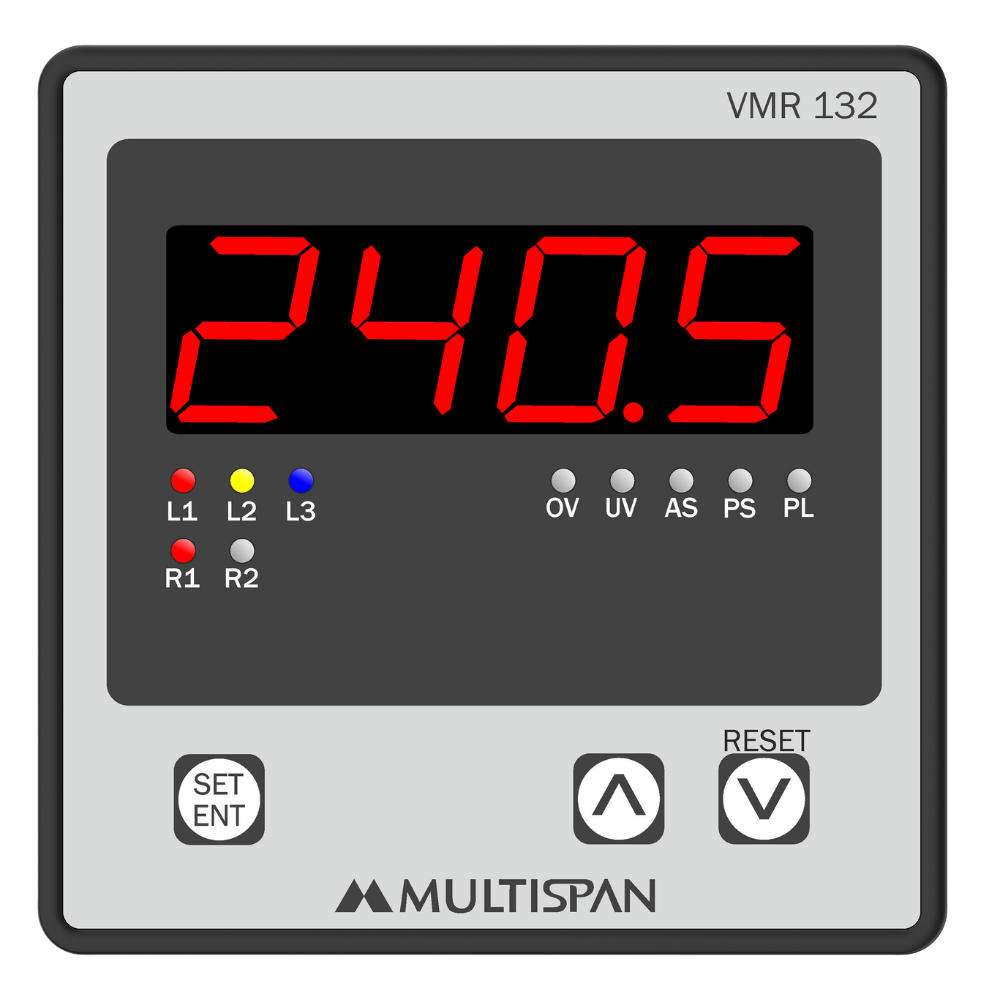

MULTISPAN VMR 132

Price 679.25 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220440 Volt (v)

Frequency : 50/60 Hertz (HZ)

Color : Black

Application : for Industrial

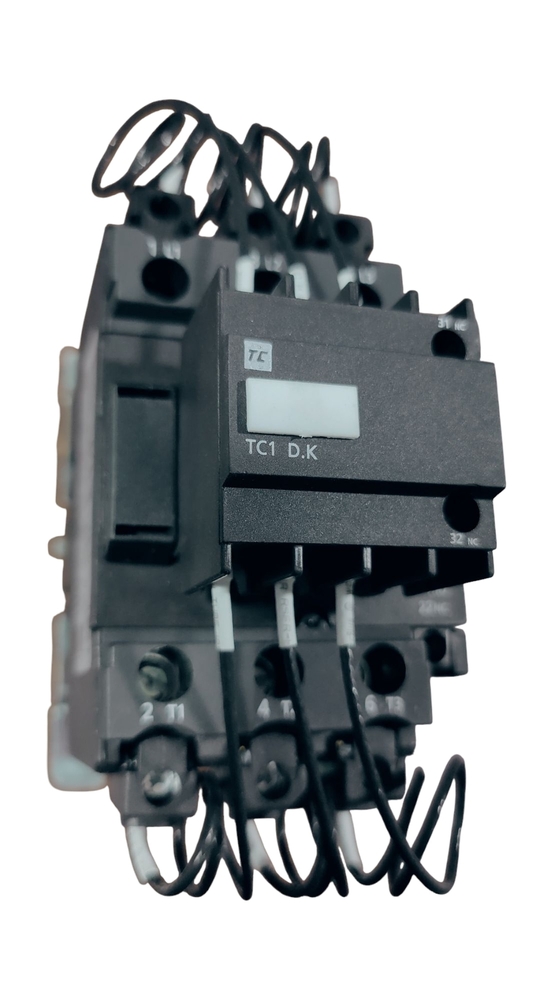

C&S CONTACTOR TC1D40K12M7

Price 6512 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220440 Volt (v)

Frequency : 50/60 Hertz (HZ)

Color : Black

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free