VLT Drives

VLT Drives Specification

- Remote Control

- Yes

- Mounting Type

- Wall Mounted, Panel Mounted

- Screen Size

- 2.5 Inch Graphical Display

- Features

- Energy Efficient, Fault Diagnostics, Programmable Logic, Soft Start/Stop

- Cable Length

- Customizable

- Sensor Type

- Current, Voltage, Temperature Sensors

- Connectivity Type

- RS485, Ethernet, Profibus, Modbus

- Weight

- 3 kg to 75 kg (Model Dependent)

- Automation Grade

- Automatic

- Drive Type

- Variable Frequency Drive (VFD)

- Phase

- Three Phase

- Speed Range

- 0.5 Hz to 400 Hz

- Load Capacity

- Up to 160 kW

- Frequency

- 50/60 Hz

- Control Type

- Vector Control, V/f Control

- IP Rating

- IP20, IP54, IP55

- Application

- Industrial Motor Control, Pumps, Fans, Conveyors

- Processor Type

- 32-bit Microcontroller

- Material

- Industrial Grade Composite & Metal

- Power

- 0.37 kW to 160 kW

- Temperature

- -10C to 50C Operating Range

- Voltage

- 200V to 690V AC

- Display Type

- LCD digital display

- Protection Features

- Overvoltage, Undervoltage, Short Circuit, Overheating

- Brake Control

- Integrated dynamic braking chopper

- Communication Protocols

- Modbus, CANopen, Profibus

- Cooling Method

- Forced air cooling

- Efficiency

- >96%

- Enclosure

- Compact modular design for easy installation

- Storage Temperature

- -25°C to +70°C

- Ambient Humidity

- <95% non-condensing

VLT Drives Trade Information

- Minimum Order Quantity

- 01 Piece

- Main Domestic Market

- North India

About VLT Drives

Following the principles of sincerity in all our business operations, we are engaged in supplying highly functional VLT Drives. These drives are procured from most reliable and authentic vendors of the market. Clients can avail our drives in different power specification as to suit their requirements. To provide a flawless range to clients, we check these drives on construction and efficiency parameters. We offer these VLT Drives at cost effective prices to clients.

Features:

- Longer operational life

- Less maintenance

- Highly efficient

Compact Modular Design for Flexible Installation

The VLT Drives with Enclosure are engineered to ease installation with their compact, modular architecture. This allows both wall-mounted and panel-mounted configurations, supporting diverse industrial setups, from small equipment rooms to large automation panels. Weight varies by model, ranging from 3 kg to a robust 75 kg, ensuring adaptability and space efficiency in any application environment.

Advanced Control and Communication

Featuring a powerful 32-bit microcontroller, these VFDs deliver precise Vector and V/f control modes for optimal motor performance. The built-in LCD digital display (2.5 inches) provides straightforward graphical feedback. For integration, multiple connectivity options are offered, including RS485, Ethernet, Profibus, CANopen, and Modbus, ensuring seamless communication with existing automation systems.

Reliable Performance and Protection

Industrial reliability is assured with forced air cooling, overvoltage, undervoltage, short-circuit, and overheating protection. The drives maintain exceptional operation in environmental extremes, supporting storage from -25C to +70C and operation between -10C and 50C. IP20, IP54, and IP55 options are available for tailored protection, and built-in fault diagnostics facilitate proactive maintenance.

FAQs of VLT Drives:

Q: How does the VLT Drive with Enclosure benefit industrial motor control applications?

A: The drive ensures efficient, safe, and reliable operation with features like energy efficiency above 96%, integrated dynamic braking, programmable logic, and advanced protection mechanisms such as overvoltage and short-circuit safeguards. Its modular, compact design supports easy installation across diverse setups, while precision control enhances the performance of motors, pumps, conveyors, and fans.Q: What is the process for installing a VLT Drive with Enclosure?

A: Installation is straightforward due to the modular enclosure and compatibility with both wall and panel mounting. After selecting the appropriate model based on power and protection needs, it can be connected to three-phase AC (200V690V) systems using the included terminal blocks. Integration with automation or remote systems is simplified with the offered communication interfaces such as RS485, Ethernet, and Profibus.Q: Where can these drives be used, and what applications are they suited for?

A: VLT Drives with Enclosure are ideal for industrial environments across India and globally. Common applications include motor control in pumps, fans, conveyors, and other machinery requiring precise variable frequency control. Their robust design, wide temperature, and voltage range make them suitable for demanding process automation, manufacturing, and HVAC systems.Q: What types of protection features are included in the VLT Drives with Enclosure?

A: These drives offer comprehensive protection, including overvoltage, undervoltage, short circuit, and overheating safeguards. They also feature fault diagnostics for maintenance and IP20, IP54, or IP55 enclosures for added environmental protection, ensuring reliability and equipment safety in industrial settings.Q: How do I remotely control and monitor the drive?

A: Remote control and monitoring are available via supported communication protocols (Modbus, Profibus, CANopen, RS485, Ethernet). The 2.5-inch LCD graphical screen displays real-time status and parameter configuration, allowing operators to make quick adjustments and diagnostics from a distance or integrated automation system.Q: What are the usage requirements regarding temperature and humidity?

A: The VLT Drives can operate in ambient temperatures ranging from -10C to 50C and can be stored safely at -25C to +70C. They are suitable for environments with non-condensing humidity levels below 95%, providing reliable performance in various climate conditions.Q: When should dynamic braking be utilized with these drives?

A: Integrated dynamic braking is essential when rapid deceleration or stopping of the connected motor is required, such as in high-inertia machinery or safety-critical applications. The built-in chopper allows safe dissipation of excess energy, preventing overvoltage and ensuring controlled braking action.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Automation Systems Category

DELTA AC MOTOR DRIVE VFD EL 1HP 3PHASE

Price 9452 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 380480V AC

Features : Compact Size, Energy Saving, Multiple Protection, Userfriendly Operation

Frequency : 50/60 Hz

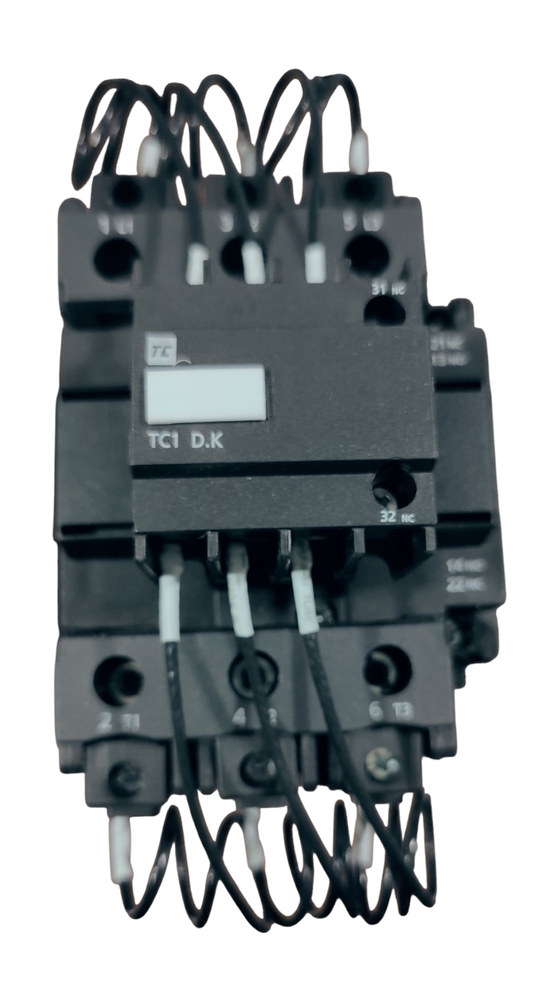

C&S CONTACTOR TC1D5011EM5

Price 3500.2 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415V AC, 50Hz

Features : High Mechanical Endurance, Compact Size, Easy Wiring

Frequency : 50/60 Hz

C&S MCB SP 20

Price 373.7 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 110215 Volt (v)

Features : Good Quality

Color : White

C&S CAPACITOR TC1D60K12M7

Price 7685.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 240 Volt (v)

Frequency : 50/60 Hertz (HZ)

Color : Black

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS