Rotary Encoders

Rotary Encoders Specification

- Drive Type

- Direct Shaft Coupling

- Frequency

- Up to 10 kHz Output Frequency

- Sensor Type

- Rotary Incremental/Absolute Encoder

- IP Rating

- IP65

- Connectivity Type

- Wired, Connector Options Available

- Mounting Type

- Flange and Shaft Mount

- Application

- Industrial Automation, Robotics, CNC Machines

- Weight

- Approx. 150 g

- Automation Grade

- Automatic

- Features

- High Precision, Durable, Easy Installation, Noise-immune Signal Output

- Speed Range

- 0-6000 RPM

- Cable Length

- 2 meters standard

- Phase

- 2 Phase Output (A/B Channels)

- Processor Type

- Optical Sensor-based Processing

- Control Type

- Incremental & Absolute

- Material

- Aluminum Alloy Body, High-Quality Sensor Components

- Power

- 5-24 VDC

- Temperature

- -20C to +85C

- Voltage

- 5-24 VDC

- Operating Humidity

- 35-85% RH (No condensation)

- Resolution

- 100/200/360/500/1000 PPR (selectable)

- Housing Diameter

- 38 mm or 50 mm (Model Dependent)

- Output Type

- NPN/PNP Open Collector, Line Driver, Push-Pull (TTL/HTL)

- Response Time

- <1µs

- Protection

- Short circuit and reverse polarity protected

- Shaft Diameter

- 6 mm

Rotary Encoders Trade Information

- Minimum Order Quantity

- 01 Piece

- Main Domestic Market

- All India

About Rotary Encoders

For our vast knowledge in this domain, we are counted amongst the most profound suppliers of Rotary Encoders. In CNC machines, these encoders are used for determining multi-axis orientation. Our expert procuring agents obtain these encoders from authentic vendors of the market. To provide a defect free range, we check these Rotary Encoders on sturdiness and performance parameters. We offer these encoders at cost effective prices.

Features:

- Highly efficient

- Light weight

- Compact design

Precision Feedback for Demanding Applications

The rotary encoder delivers high-resolution position and speed feedback essential for advanced automation tasks. Its selectable resolutionfrom 100 to 1000 pulses per revolutionmakes it suitable for both coarse and fine control requirements. Industrial-grade materials ensure long-term reliability, especially where precise motion is critical, such as in robotics, CNC machines, and factory automation systems.

Outstanding Connectivity and Protection

Supporting multiple output types, including NPN/PNP open collector, line driver, and push-pull (TTL/HTL), this encoder integrates smoothly with varied control systems. Built-in short circuit and reverse polarity protection safeguards the device and connected equipment, reducing downtime and increasing operating confidence during setup and ongoing use.

Versatile Mounting and Installation

The encoder offers both flange and shaft mounting options, allowing seamless integration into existing machine designs. With its IP65-rated aluminum alloy housing and standard 2-meter cable, installation is straightforward and robust, even in challenging industrial environments. Fast response time ensures accurate real-time measurement for dynamic applications.

FAQs of Rotary Encoders:

Q: How can I select the appropriate resolution for my application?

A: The rotary encoder provides selectable resolutions from 100 to 1000 pulses per revolution (PPR). Choose a lower PPR for basic position feedback or a higher PPR for precise speed and movement control in applications such as CNC machining and robotics.Q: What are the main benefits of using this encoder in industrial automation?

A: Key benefits include high precision, rapid response time (<1s), noise-immune signal output, and robust protection measures such as IP65 rating, short circuit, and reverse polarity safeguards. These features help maximize uptime and ensure reliable data feedback in demanding automation environments.Q: When should I use incremental versus absolute control types?

A: Incremental encoding is ideal for determining relative position or speed in systems like conveyors and motors, while absolute encoding is necessary for applications that require the encoder to retain exact positional data during power loss, such as in robotic arms.Q: Where can this rotary encoder be installed?

A: The encoders flange and shaft mounting options, along with a choice of housing diameters (38 mm or 50 mm), make it suitable for installation in a variety of machines, including automated systems, CNC equipment, and robotic platforms within industrial settings.Q: What is the process for connecting and powering the encoder?

A: Connect the encoder using the standard 2-meter cable to your control system; select the desired output type (NPN/PNP open collector, line driver, or push-pull TTL/HTL). Power the device with 5-24 VDC, ensuring proper polarity, leveraging built-in protection for reliable operation.Q: How does the encoder ensure reliability in harsh environments?

A: The aluminum alloy body, IP65 enclosure, and high-quality sensor components protect against dust, moisture, and vibration. It operates within temperatures from -20C to +85C and humidity between 35 to 85% RH (non-condensing), providing consistent performance even in industrial conditions.Q: What usage recommendations help extend the encoders lifespan?

A: To maximize lifespan, mount the encoder securely using appropriate methods, avoid condensation, keep electrical connections stable, and operate within specified voltage and speed ranges (0-6000 RPM, 5-24 VDC). Routine inspections and adherence to installation guidelines support long-term accuracy and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Automation Systems Category

C&S LINKSET CSET1033 C

Price 111 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard Sizes

Remote Control : Yes

Warranty : 1 year

Features : Good Quality

C&S CAPACITOR TC1D40K12M7

Price 6512 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard Sizes

Remote Control : Yes

Warranty : 1 year

Features : Good Quality

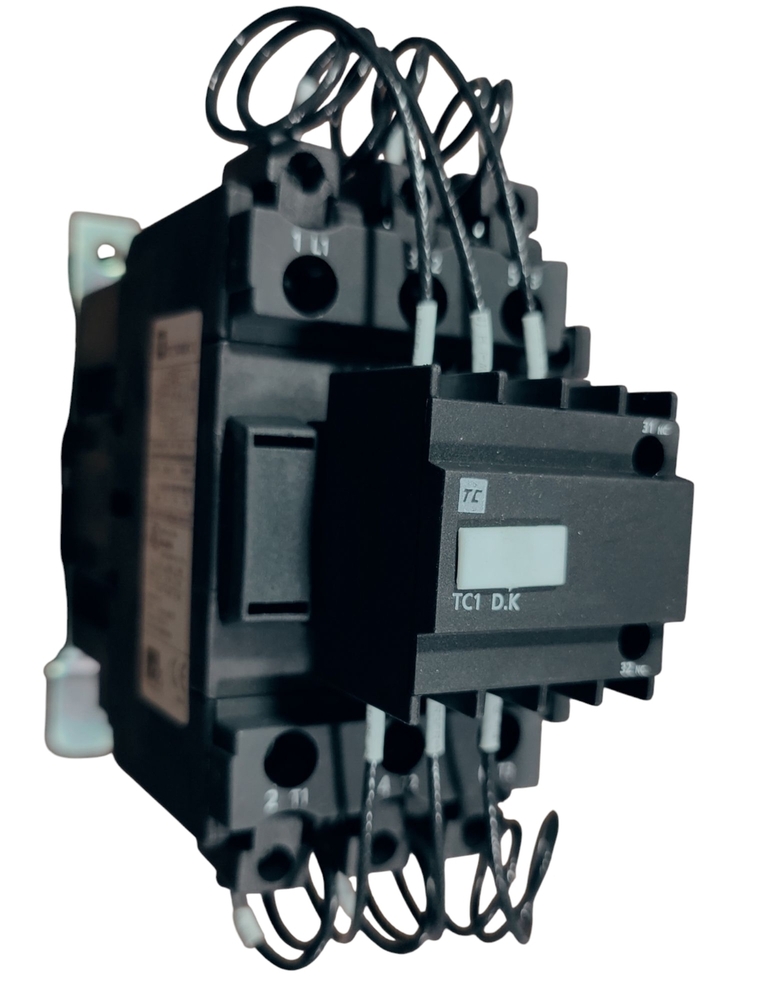

C&S CONTACTOR TCA3DN22 BD

Price 965.7 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard Sizes

Remote Control : Yes

Warranty : 1 year

Features : Good Quality

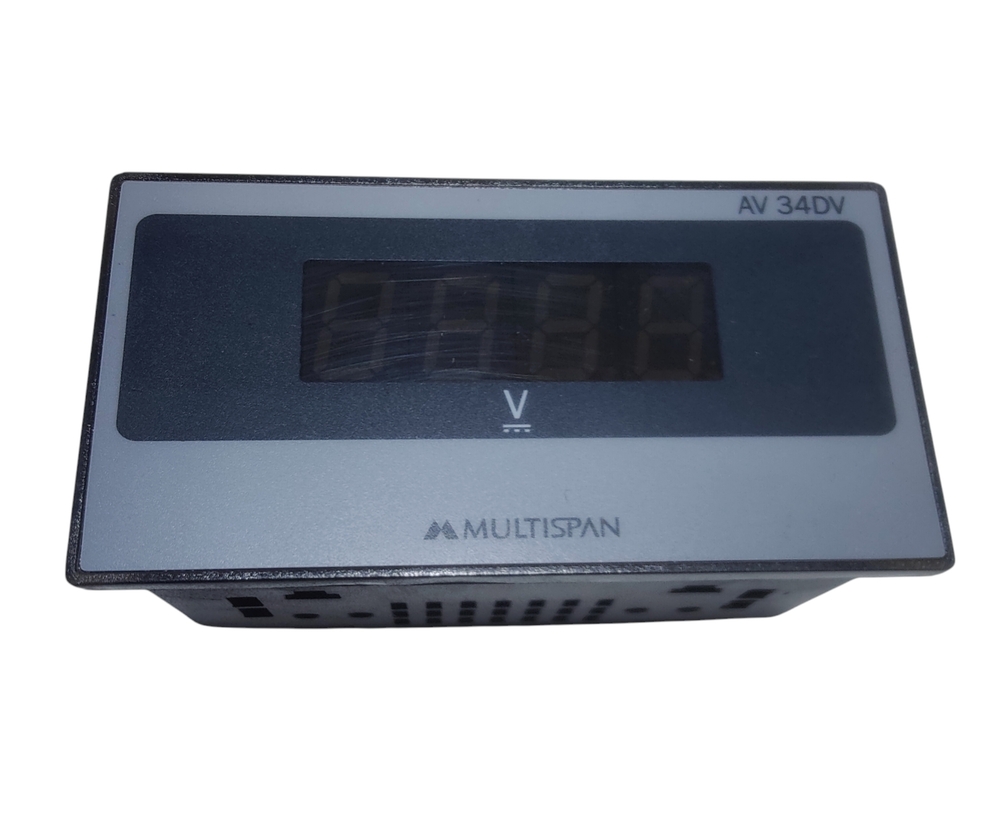

MULTISPAN AV 34DV

Price 635.25 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard Sizes

Remote Control : Yes

Warranty : 1 year

Features : Good Quality

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS