Automation Panels

Automation Panels Specification

- Weight

- 20-40 kg

- Sensor Type

- All Standard Industrial Sensors Supported

- Control Type

- PLC-based

- Cable Length

- Customizable as per requirement

- Speed Range

- Variable Drive Supported

- Frequency

- 50-60 Hz

- Mounting Type

- Wall Mounted/Panel Mounted

- Application

- Industrial Automation, Process Control

- Processor Type

- Industrial PLC

- Load Capacity

- Up to 100A

- Drive Type

- VFD/Soft Starter Compatible

- Features

- Short Circuit Protection, Overload Protection, User-friendly Interface

- Remote Control

- Yes

- Phase

- Three Phase

- Connectivity Type

- Ethernet, RS-232, RS-485

- IP Rating

- IP54

- Screen Size

- 7-15 Inches (for HMI integrated)

- Automation Grade

- Automatic

- Material

- Mild Steel (MS) body with powder coating

- Power

- 3-15 kW

- Temperature

- Operating range: 0C to 50C

- Voltage

- 415V AC

Automation Panels Trade Information

- Minimum Order Quantity

- 01 Piece

- Main Domestic Market

- All India

About Automation Panels

Holding the rich domain expertise, we are efficiently meeting the needs of our clients by supplying a wide range of Automation Panels. These panels are suitable for controlling devices like drum operation, aggregate weighing, auto water dispensing and aggregate conveyor control. We obtain these panels from certified vendors of the market after conducting several market surveys. Clients can avail our Automation Panels in customized sizes and specifications as per their requirements.

Features:

- Light in weight

- Shock proof

- Easy to install

Advanced Features for Industrial Reliability

Constructed with powder-coated, corrosion-resistant mild steel, our automation panels deliver longevity and protection in challenging environments. Equipped with integrated MCB/MCCB circuit breakers and electroplated copper/aluminum bus bars, they support up to 100A load while ensuring consistent, protected operations. Ventilation fans, audio-visual alarms, and a lockable door all add layers of safety and user assurance.

Flexible Control and Seamless Connectivity

Featuring PLC-based automatic control and touch screen HMI (optional), these panels offer easy, remote operation and system monitoring. Multiple digital and analog I/O channels interface with standard industrial sensors, supporting wall or panel mounting to suit diverse installation needs. Ethernet, RS-232, and RS-485 connectivity ensure seamless integration with your automation network.

FAQs of Automation Panels:

Q: How does the hinged and lockable panel door enhance security and convenience for operators?

A: The hinged and lockable panel door provides secure access to internal components while allowing for quick inspection or maintenance through its viewing window. This design helps prevent unauthorized entry and facilitates safe, efficient operations in industrial settings.Q: What is the benefit of the powder-coated, corrosion-resistant enclosure finish?

A: Powder coating creates a durable and protective surface on the panel, minimizing the risk of corrosion and wear over time. This finish is especially beneficial for harsh industrial environments, extending the panels lifespan and maintaining its aesthetic quality.Q: When should I choose a touch screen HMI display for my automation panel?

A: Opt for an HMI touch screen if you require intuitive, real-time monitoring and direct interaction with your process controls. It is especially useful when operators need to frequently adjust parameters, access data, or troubleshoot systems on-site.Q: Where can these automation panels be installed?

A: The panels are designed for versatile mounting options, including wall-mounted and panel-mounted setups, making them suitable for various industrial automation and process control environments across manufacturing plants or facilities.Q: What process does the integrated PLC-based control system manage?

A: The industrial-grade PLC automates and manages critical control processes such as machine operations, load monitoring, and sensor integration, enabling precise, programmable industrial automation while supporting remote and local oversight.Q: How does the ventilation and cooling system safeguard the panels components?

A: Built-in ventilation fans regulate internal temperatures, ensuring optimal cooling. This prevents overheating and prolongs the lifespan of sensitive electronic components, even under continuous operation between 0C and 50C ambient temperature.Q: What are the main usage and benefits of having audio/visual alarm provisions in these panels?

A: Audio/visual alarms provide immediate alerts for abnormal operating conditions, such as overloads or faults. This feature enhances workplace safety, reduces potential downtime, and assists operators in responding swiftly to system events.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Automation Systems Category

C&S MPCB TCMS-32SE-32

Price 4273.5 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Highgrade thermoplastic and metal components

Features : Short circuit and overload protection, adjustable current setting, compact design

Remote Control : Yes

Voltage : 415V AC

C&S RCCB CSRB4P32A30-10kA

Price 1780 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Plastic, Copper Contacts

Features : High Sensitivity, Safety Interlock, Compact Size, Simple Operation

Remote Control : Yes

Voltage : 415 V AC

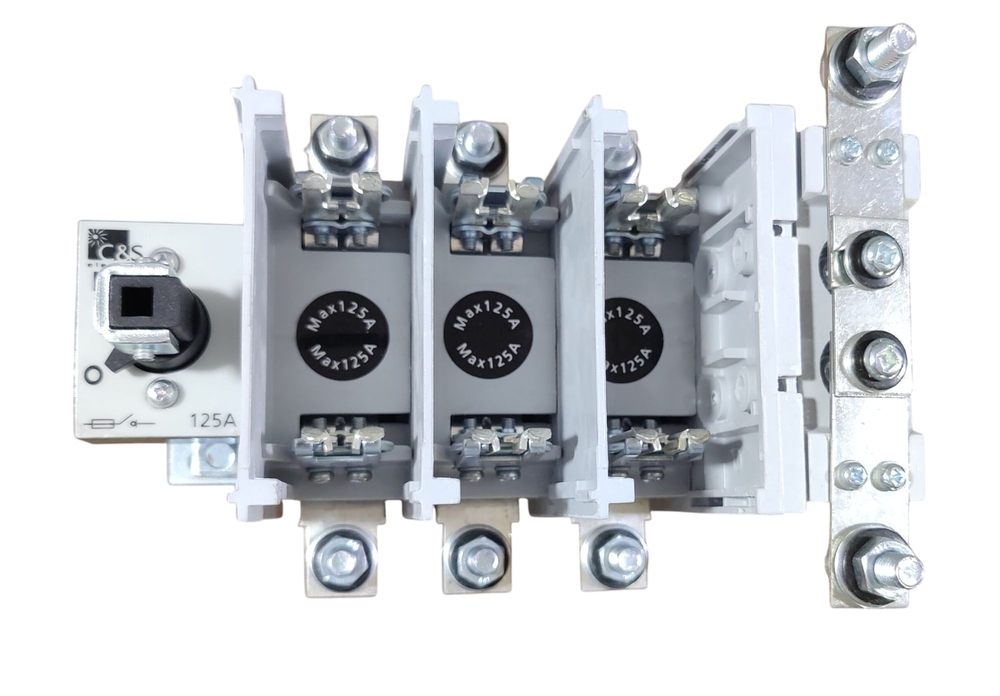

C&S SWITCH CONNECTOR FUSE UNIT CSSDF125D3N

Price 3515 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Plastic Metal

Features : High accuracy

Remote Control : Yes

MULTISPAN LR35

Price 907.50 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 100270V AC Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free